Contact us

Thermal Processes

The circular economy and the decarbonisation of our industry are driving us to reevaluate our production processes, and particularly those which are the most energy consuming.

In practice, in the mineral industry sector, thermal processes trigger new developments to improve their efficiency and incorporate new primary and secondary materials.

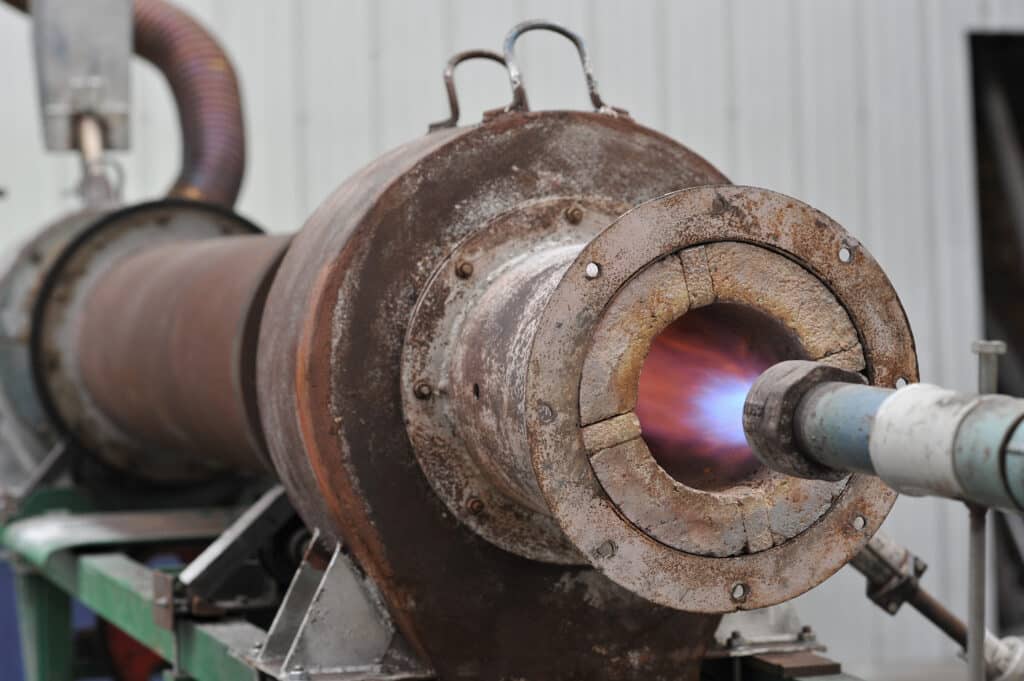

The CTP is working on a number of research projects in this area, including new compositions of clinker. It has available laboratory and pilot equipment including several rotary furnaces and will in the near future construct a clinkerisation furnace allowing its field of investigations to be widened.

| Equipments | Operating mode | Capacity | Calcination tube | Hot gas generator | Processing of outgoing gases | |

|---|---|---|---|---|---|---|

| Rotary furnace 1 |

|

Operating in counter-current or cocurrent mode | Max temperature: 1 000 °C | Exterior/interior diameter: 330/210 mm | Burner operating on naturel gas with the addition of compressed air - Pyronics 16 HBT model (power 150 kW) | An extraction fan captures and sends gases to a cyclone dust collector or a filter and then to the stack |

| Feed rate: 5 à 15 kg/h (depending on the material an the retention time) | Effective length: 1 540 mm | |||||

| Maximum particle size: 10 mm (avoid powdered materials) | Inner lining: alumino-silico refractory | |||||

| Adjustable gradient of 0 to 4% | ||||||

| Retention time: between 15 and 45 minutes | Adjustable rotation speed from 0 to 1,5 turn/min | |||||

| Rotary furnace 2 |

|

Operating at counter-current | Max temperature: 1 150 °C | Exterior/interior diameter: 800/600 mm | Natural gas burner (750 kW) and combustion air blower (1000 Nm³/h - 5,5 kW - 85 hPa) | Post-combustion (static oven with natural gas burner operating to 850°C |

| Feed rate: 50 to 150 kg/h (depending on the material an the retention time) | Total/length op operation: 9180/8170 mm | Cyclone | ||||

| Maximum particle size: 20 mm (avoid powdered materials) | Inner lining: alumino-silico refractory | Neutralisation of gases (static mixer and neutralising substance injection device) | ||||

| Gradient fixed at 2% | Bag filter (filter area of 62,8 m² and extraction fane 11 kW - 5400 m³/h to 250°C - 27 hPa) | |||||

| Retention time: between 45 and 90 minutes | Adjustable rotation speed from 0 to 2,5 turns/min |

All

Our expertises